Capabilities

Introduction into G-TEM Capabilities

G-TEM possesses a full complement of capabilities in order to achieve OEM requirements from large in-house cast die manufacturing, material procurement, world class production capabilities via fully automated large AIDA stamping process and complex automated multi robot assembly lines for Ultra high strength steel, Aluminium & steel.

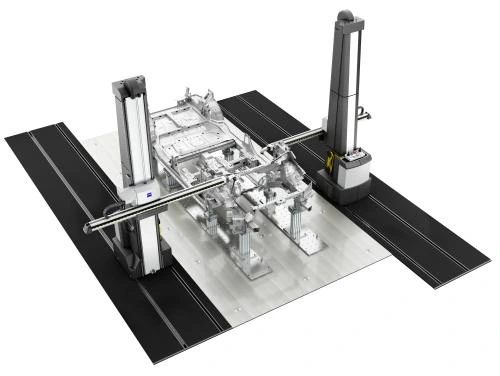

Stamping

- Hybrid capability – UHSS / Aluminum / Steel

- x9 – Fully Auto high speed AIDA Transfer lines (1920 Width * 6mm Material Thickness)

- x5 – Large Automated AIDA Progression lines (2000 Width * 6mm Material Thickness)

- x10 – Automated Progression lines with Profile blank capability

- Automated closed loop scrap reclaim facility.

- x5 Try out Presses ranging from 500 ~ 1000 Ton

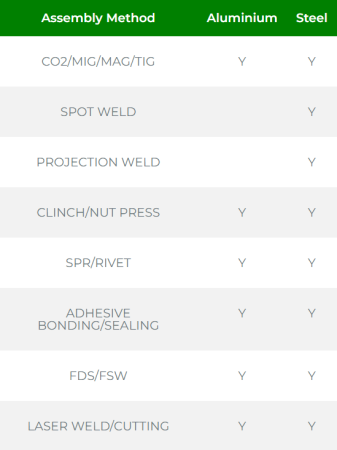

Assembly

- Fully automated complex assembly lines

- Automated stamp nut capability (Profil & SPAC)

- Automated SPR technology

- Spot & Projection

- Laser Welding

- Friction Stir Welding

- Bonding

- Various NVH applications

Wireforming

- Highly flexible wire bending / spring forming solution using 6-axis CNC Wire Formers.

- Ability to form wire in a vast range of OD’s. (3~ 14mm)

- Cold Forming heading operations.

Quality

IATF 16949 & ISO 9001 Accredited

JLR Q Award from Jaguar Land Rover

Best Class Quality Achievement with 4 Major OEM's

Q&D Awards from Multiple Customers

- Fully equipped Metrology centre

- Automated CMM measurement systems

- 3D laser & White light scanning capability

- In-house Material testing capability

- Macro testing facility

- Established audit system

- Full tear down facility

Logistics & Material Management

Logistics

- Fully integrated automotive ERP system interfacing with customers via automotive standards

- Side & rear vehicle loading with 20 minute turnaround time

- Full Automated storage and retrieval system

- Extensive warehousing facilities

- Fully compliant lot control management

- JIT Sequenced supply for complex assemblies

- Small parts Kanban consolidation

Material Management

- Fully automated lot control management for material

- Wide ranging supply base across UK , EU & Asia – both Service centers and mill direct.

- Blank – Via profile , sq shear, Laser.

- Ability to take Mill direct coil up to 20 ton

Die Manufacturing

- X4 Large 5 axis NC Machining Centres

- X6 Small / Medium NC

- Wire Cutting and EDM

- Large conventional machine shop & bench workers

- In House Die design at G-TEM – Allows full Process Planning

- Spotting presses for Die try out

- Grinding facility

- Full gantry cranes across all press areas of production

- Full CAD/ CAM linkage across all NC machines

Procurement

We Can Procure:

- Fasteners

- Fixings

- Tubular Components

- Aluminium Extrusions

- Material

- Machinery

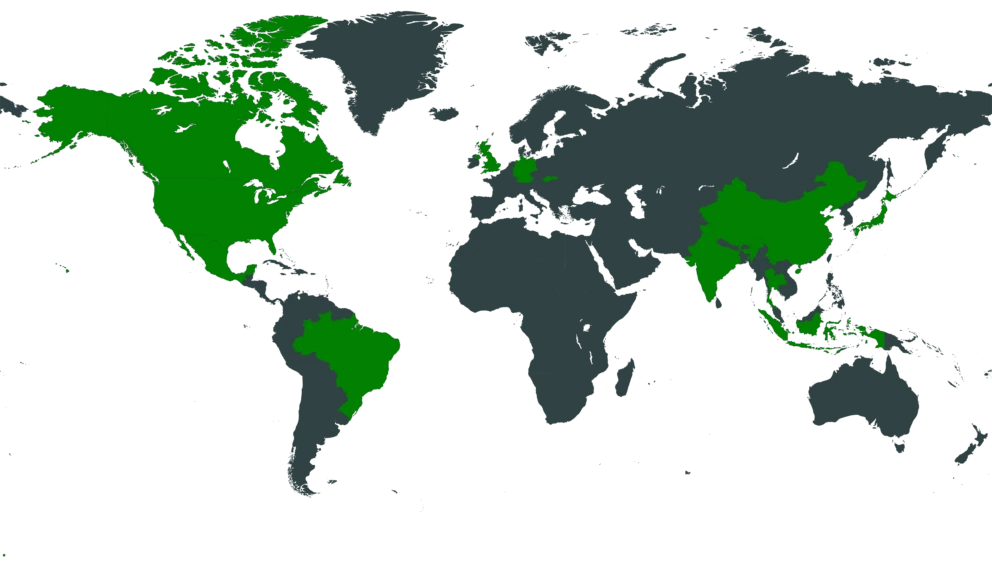

Any requirement you may have we can deliver via global procurement links into multiple regions across the globe.

Our established linkages provide prompt response and quality.

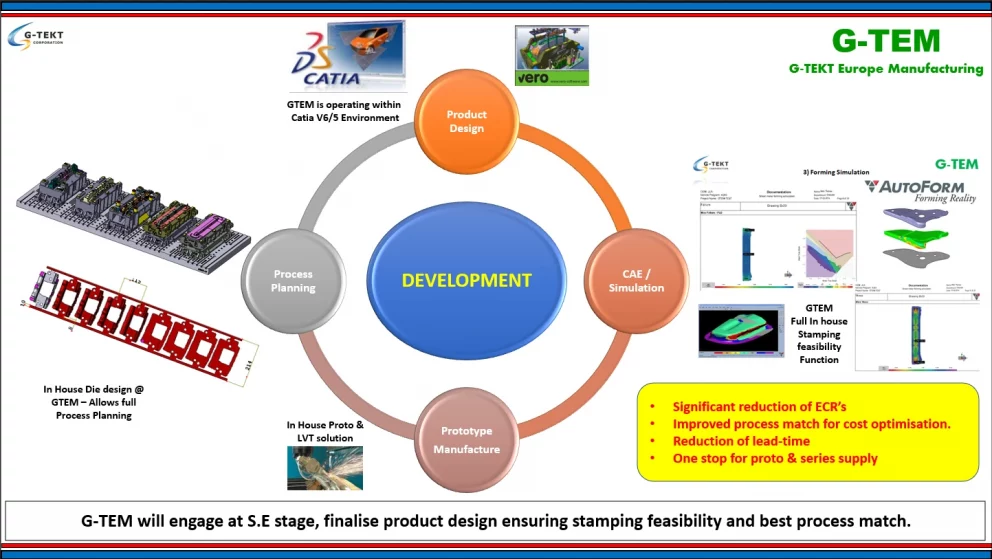

Design, CAE, Simulation

- G-TEM receives data , interrogates, disseminates then carries out full FCR analysis with cost optimization / process efficiency and manufacturability as key points and delivers re-worked CAD back to engineer as simultaneous engineer service with manufacturing capability embedded.

- Full Formability & Simulation reporting

- Full Automotive complaint software

Prototyping & Low Volume

New Investment

- G-TEM has a commitment to ensuring all relevant technological advancements within our sector as well as emerging markets are fully assessed and deployable should a customer need support in this particular area of the supply web.

- EV products are certainly an area G-TEM has focused on and has developed a technology partnership with Fuji Springs in Japan for Primatic battery case manufacture.

- New state-of-the-art E-Coat in-house line is set for system up in 2024 as we see a trend for this within battery area.

- X2 1MWp Solar farms installed at Gloucester facilities in 2022 to support our net-zero targets.

- A further 2MW expansion at original Gloucester facility completed in 2023, bringing total capacity to 4MW across both Gloucester sites.